Candles are one of the few universal goods that just about every individual can benefit from. In fact, this market is so large that the global Candle Market was valued at USD $6.8 Billion in 2021 and is set to surpass USD $9.9 Billion by 2028.

Candle buyers love having these sweet smelling wax creations in their homes, office spaces, to give as gifts, and to spark joy for the entire holiday season. Whether it’s clean linens and hibiscus flowers or sugar cookies and pine trees, there are candles for every occasion, emotion, and season. But, how are these delightful creations actually created? Furthermore, how do these scented wax wonders go from wicks and melted mixtures to the beautiful varieties found on store shelves across the nation?

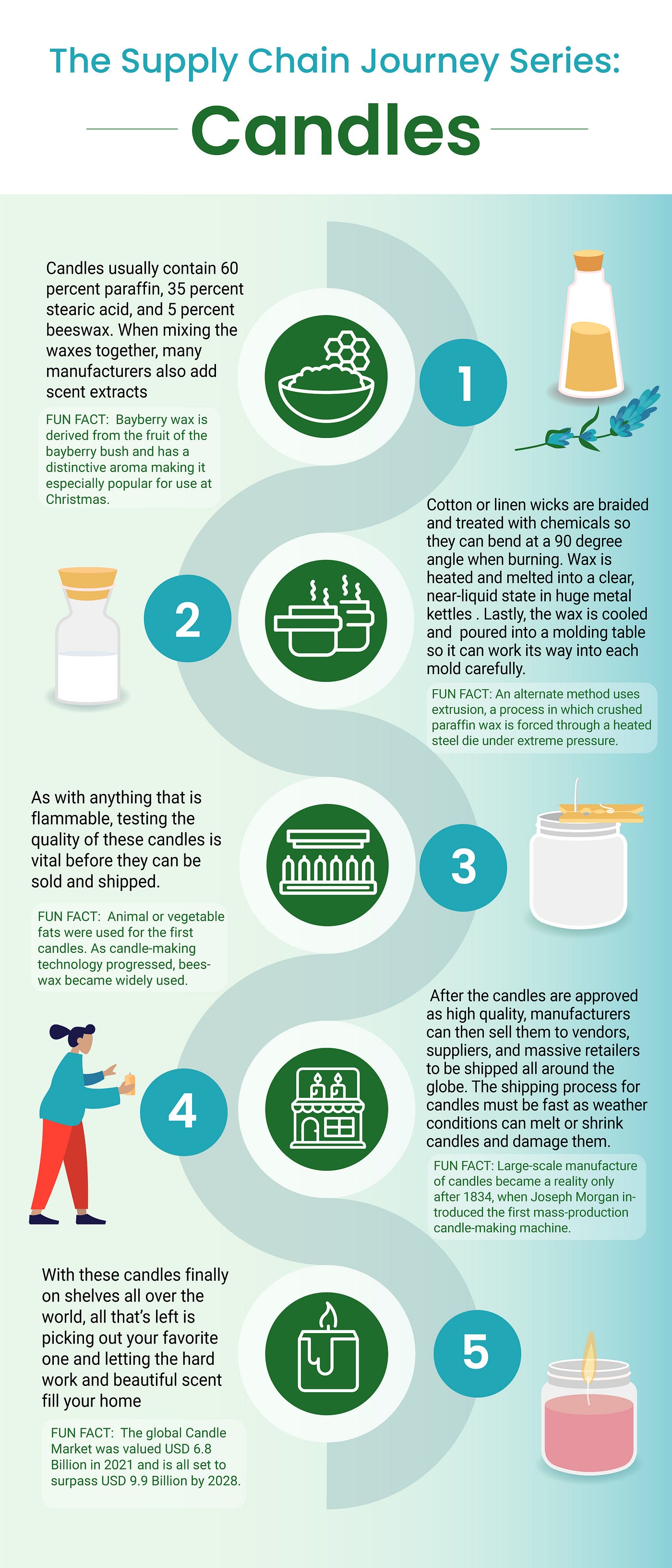

As part of the new supply chain journey series by Stimulus, we’ve chosen to break down the entire creation process and journey of the average candle to show exactly what makes these pleasant products such a ‘breath of fresh air,’ literally. Without further ado, let’s analyze this aromatic art and see what makes it so incredible below.

The Materials

The candle making process all starts with the materials and how they are carefully chosen for different scents, burn temps, and effects. Although the materials may have changed slightly, the art of candlemaking has remained surprisingly similar to the original production processes through the years.

In the United States, standard commercial candles usually contain 60% paraffin, 35% stearic acid, and 5% beeswax. When mixing the waxes together, many manufacturers also add scent extracts to give each candle its lovely smell. According to Taste of Home, pumpkin and vanilla are the most sought after candle scents in America. However, Beeswax candles are also highly popular and rely on their natural honey smell.

During the holiday season, Bayberry wax is also often found in candles and it is derived from the fruit of the bayberry bush and has a distinctive aroma making it especially popular for use at Christmastime.

The Production Process

The production of the average candle is incredibly fascinating and requires several steps for success.

First, the cotton or linen wicks are braided and treated with chemicals so they can bend at a 90 degree angle when burning. Next, the wax is heated and melted into a clear, near-liquid state in huge metal kettles while the wicks are taped to the top of each wax mold. Lastly, the wax is cooled to slightly above its melting point and poured into a molding table so it can work its way into each mold carefully.

An alternate method uses extrusion, a process in which crushed paraffin wax is forced through a heated steel die under extreme pressure.However, this forms long wax cylinders that are more akin with the candle sticks you would use in a candelabra.

Quality Control

Once these candles are produced and scented accordingly, there is one final step before they can be sold and shipped. This step is often referred to as the quality control process.

As with anything that is flammable, testing the quality of each candle is vital before they can be sold and shipped to consumers and suppliers. Testers measure the candle’s flammability, burn time, and wick quality to ensure the candle is safe and of a high quality as well. A quality candle should burn one hour for every 1 inch in diameter of the actual candle size. It should also have a wick that doesn’t create a flame which extends past the candle jar lip and a scent that permeates nicely when it is burned.

Selling and Shipping

Large-scale manufacturing of candles became a reality only after 1834, when Joseph Morgan introduced the first mass-production candle-making machine. Now, the manufacturing process takes only a day before the shipping process can begin.

After the candles are approved as high quality, manufacturers can then sell them to vendors, suppliers, and massive retailers to be shipped all around the globe. The shipping process for candles must be fast as weather conditions can melt or shrink candles and damage them. A candle that is damaged in shipment can quickly become worthless to a buyer as wet wicks, melted candles, and dried out candles all pose potential threats to users. As such, candles must be packaged thoroughly and sent with speed shipping.

Smells Like Money!

Now that the products are shipped, retailers can place the candles out on shelves for sale. According to Candle Science, candles are priced accordingly: Mass market: $7 to $11. Mid-market: $13 to $18. High-end or “prestige”: $19 to $28+

With these candles finally on shelves all over the world, all that’s left is picking out your favorite one and letting the hard work and beautiful scent fill your home with joy and peace!

Stay tuned for more supply chain journeys to come, and feel free to watch the ‘How It’s Made: Candles’ episode below to see some more of this journey in action:

.png)

.png)

.png)